Why it`s necessary to apply corosion protection for concret?

Concrete fermenters and tanks require a corrosion protection system to maintain the condition for continuous use, without the need for periodic maintenance actions. Concrete chemical can not cope with the stress being put in during the fermentation process.

What affects concrete structures?

Even after a short time of commissioning, concrete structure can be affected by aggressive chemicals, resulting from biomass or biogas processing. Moreover, the use of plant and animal residues and residues from slaughterhouses, storage oils and fats, increases the corrosivity of substances in the tank. The components for the chemical impact are methane, ammonia, sulfuric acid, hydrogen sulfide and other organic acids.

Not every protection system is effective

Conventional protection systems for biogas installations do not provide sufficient protection against aggressive substances. Solvent-based protections are responsible for instance osmotic blistering and decreased resistance by exposure to acids. By measuring the thickness each yearl, you will notice a difference of 1-2 cm. Corrosion can cause leaks and periodic investment to repair the structure. To these adds the downtime of the tank.

Below you can see two effects of aggressive substances:

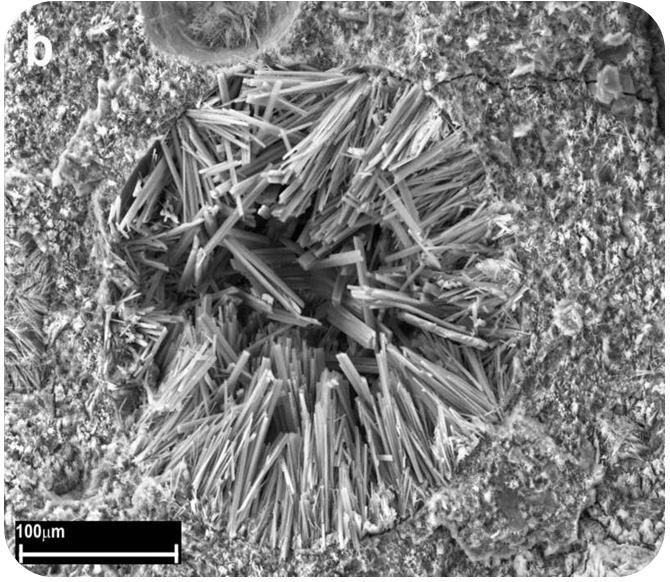

Expansion effect

Due to sulfate attack the sulfate ions react with responsive clinker materials in the concrete. This voluminous crystallization leads to expansion effects of the concrete.

Concrete erosions

Due to low acid resistance Ca-minerals are disintegrated out of the concrete and effectuate concrete erosions.

You can save maintenance costs for concrete structures. You have a specialized team ready to apply protection systems adapted for aggressive substances, present in the tank. Moreover, contact us now and get free consulting! Here you have our contact details.