Case study: Refurbishment of a pool filter. See the benefits and application process!

The project was developed in Stade, Germany. Year, 45,000 visitors enjoy the outdoor pool in Hollern-Twielenfleth, located in proximity of the river Elbe.

.

Corrosion Problems

Filtering tank, strongly affected by corrosion, has been refurbished. The measure significantly reduced operational costs. The project also reduced the quantity of water by 50%, reducing costs and environmental impact.

Reconditioning before being deployed, filter affected by corrosion involves high consumption of energy and water. Its performance was affected by bottlenecks caused by different materials, water quality is affected by rust particles. Much of the water was redirected to the treatment plant. If you ask which is the capacity of the basin, approximately 80 m3 (80,000 liters), to meet the requirements of sanitation.

(Filter affected by corrosion

Technical information

Project: refurbishment of an internal steel filtration vessel ( 38 years old)

Size: about 5 meters high, 3 meters in diameter and 3 filtration units

Product used: Proguard CN 200

Application Process

Internal walls of the vessel were blasted to remove corrosion and to obtain the optimal degree of roughness. Existing chlorides, determined by Bresle method, were removed by high pressure cleaning. Subsequently, the product was applied manually and airless spray.

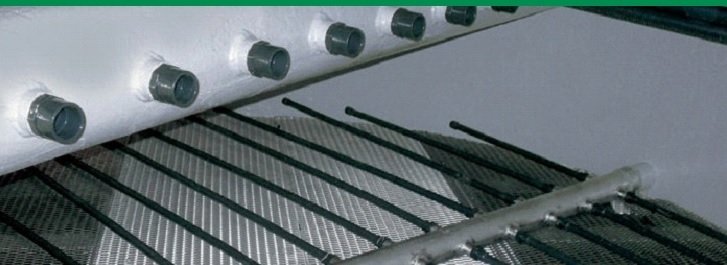

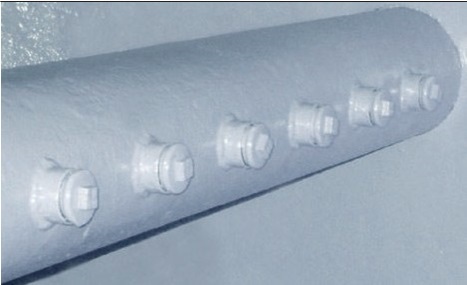

To complete the process, the company Norbert Reinken installed a series of stainless steel tubes.

Through the actions mentioned above, the required amount of water was significantly reduced. Every day, they only need 40-50 m3, meaning a reduction of approximately 50% compared to the initial amount.

(after reconditioning)

For more information regarding corrosion protection applications, we provide you with the following contacts. Choose reducing maintenance costs! Together we will identify the best technical solution for your business