Corrosion protection for industrial flooring

Corrosion protection for industrial flooring:

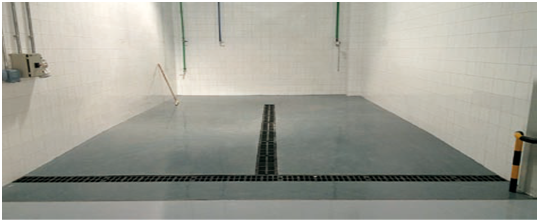

Renovation of a Toyota vehicle workshop and the related car wash

Technical specifications:

Area: 500 sq.m.

Product features: resistance to mechanical stress, very good chemical resistance

Product used: CP-SYNTHOFLOOR BETA 8016 (Primer) and SYNTHOFLOOR + CP-8463 (top layer)

Flooring systems CP-SYNTHOFLOOR BETA 8016 (primer) and CP-SYNTHOFLOOR 8463 as self leveling topcoat are applied simply by conventional hand tools. Both systems are solvent-free, hence the application procedure is lot less harmful.

Advantages of using CP-SYNTHOFLOOR BETA 8016 + CP-SYNTHOFLOOR 8463 for industrial flooring:

· Solvent free

· Excellent chemical resistance

· Abrasion Resistance

· Very high compressive strength

· Fast curing times

· Wear resistant surface, easy to clean

· Simple application by rake

Our team can help you to choose the most effective solutions!