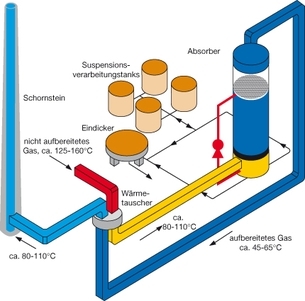

B-Team Corrosion Protection offer advanced corrosion protection systems and corrosion materials for Flue Gas Desulfurization Plants. Our materials provide resistance against permeation, chemicals, abrasion and corrosion.

We offer you protection systems based on CHEMOLINE rubber linings and COROFLAKE synthetic resin. Rubber linings materials are applied in areas where temperatures do not exceed 100° C. Their excellent chemical resistance, together with equally good resistance against abrasion, allow them to be used for corrosion protection in absorbers, tanks, circulation and distribution pipes.

CHEMOLINE 4B and CHEMOLINE 4CN are the primary rubber products offered for lining in desulfurization stations. CHEMOLINE 4A is the product for conventional lining of vessels and pipes, where the vulcanisation process requires either hot air or steam under pressure.

The COROFLAKE range of lining and coating systems provide exceptional chemical resistance at a broader temperature range than rubbers and are typically used within FGD Plants for the lining of flue gas ducting, gas/gas re-heaters and tanks. COROFLAKE coatings can be used in applications with temperatures of up to 230° C.